Just How Strong is Ultrasonic Battery Spot Welding?

Spot welding is a type of resistance welding used to weld metal sheets together. Also known as resistance spot welding, it applies external force at singular points or spots, to press and join the surface area. This older form of welding metals to sheets is usually done by passing an electric current without a filler. TECH-SONIC is a market leader in Ultrasonic Metal Welding with long-established expertise in ultrasonic spot welding.

Resistance spot welding is very important in the manufacturing industry. It is fast, simple, and cost-effective. But its reliability depends on several variables such as the careful control of pressure and electric current. Deviating from specified parameters causes sub-standard welds resulting in an unsatisfactory finished product. Poor products adversely affect the customer’s satisfaction and the manufacturer’s revenue.

One of the quality-control measures for battery spot welding is its joint strength. Due to the growing trend of using light materials, mild steel sheets are now replaced with aluminum and other alloys. Difficulty in welding these materials lead to the development of ultrasonic spot welding.

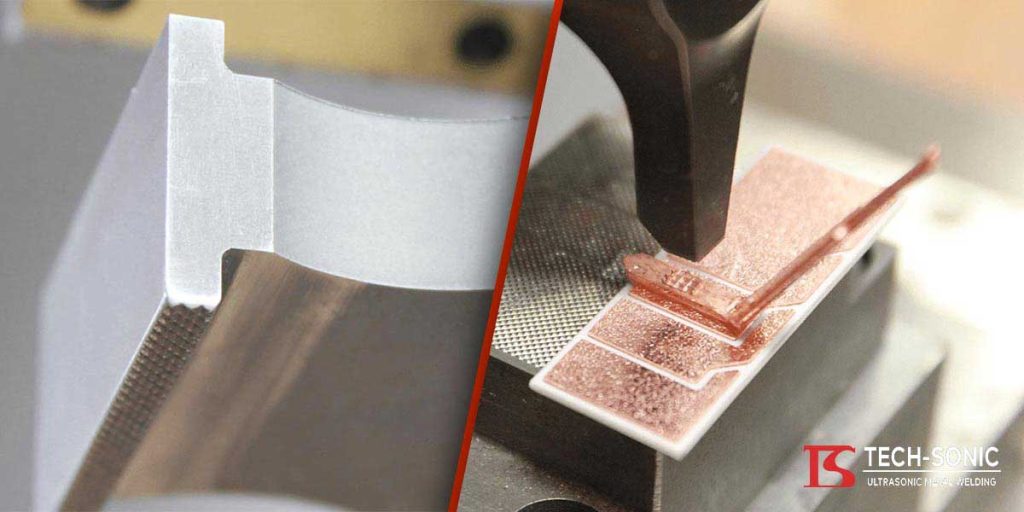

This spot welding process is more efficient in joining similar and dissimilar solids. The high-frequency vibratory energy produces a solid-state weld when the components are subjected to pressure. This is applicable for both thin and thick sheets of alloys, where the joint is created without melting the base.

In addition, learn the Recent Advances in Welding EV Batteries using ultrasonic spot welding method.

What is Ultrasonic Battery Spot Welding?

Ultrasonic battery spot welding is a process where materials are joined at certain points with no specific joint designed on its interface. This process is used in the micro-joining of metal or plastic products to multiple parts, such as metal sheets of complex forms. It is also used in soldering, metal welding, hermetic sealing, and thermoplastic joining.

This technology was integrated into the manufacturing industry in making joints of alloy and plastics. In short, this is a solid joining technique.

Advantages of Ultrasonic Battery Spot Welding

Using ultrasonic spot welding technology in the manufacturing industry has many advantages. Aside from speed, it includes machine durability and cost-effectiveness. It is ideal for melding components because it creates clean and reliable welds.

What is a Spot Welder Used For?

It is widely applied in the industries of electronics, aerospace, metal furniture, automotive, and medical equipment. This includes blister packs that are tamper-proof and vacuum-sealed. It may be automated by integrating it with robotics manipulation technology. This is quite common in high-volume assembly lines.

How Strong is Ultrasonic Battery Spot Welding?

Ultrasonic battery spot welding technology creates joints that are stronger compared to other spot weld techniques. Weld strength is critical because of the costly materials used in the manufacturing industries.

In a study on ultrasonic welding, defect-free sturdy spot welds were accomplished. The micro-hardness of the spot weld between similar and dissimilar joints was near-constant. The tensile lap shear failure load increased with increasing welding energy. This met the standard of AWS D17.2 for spot welding.

The quality of spot welds is therefore critical in manufacturing defect-free products. This is especially applicable in the aerospace and automotive industry. Structural durability and integrity are important.

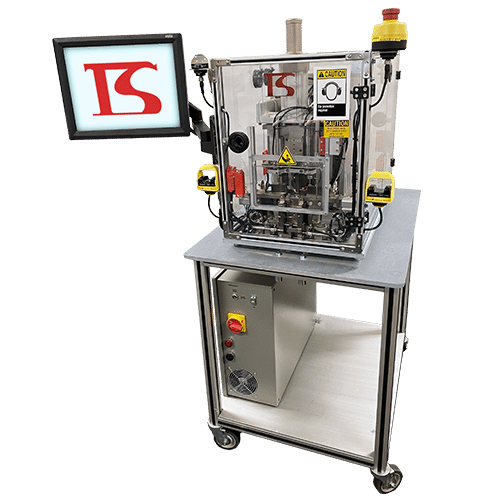

Ultrasonic battery spot welding is an excellent method for creating strong joints. A high-quality weld can be achieved using the right equipment such as the US-3620SH Heavy Duty Ultrasonic Spot Welder for Pouch/Prismatic Battery Welding. Joining sheets of similar and dissimilar materials has never been so fast and so easy!

Featured Products

CLC Large Cable Termination Welder

US-3620STH

CLC Pouch/Prismatic Battery Welder

US-3620SH

CLC Ring Termination Welder

US-3620SRT