US-3620STH

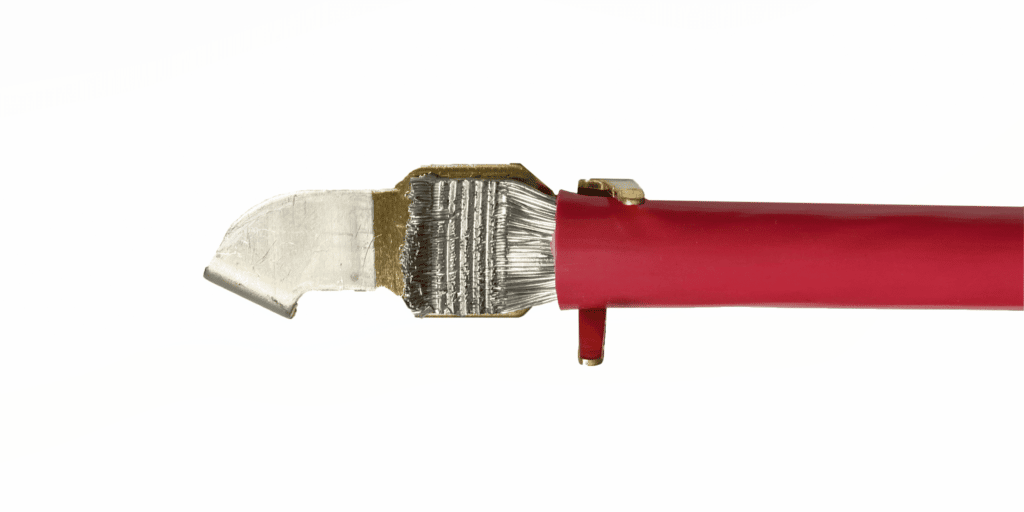

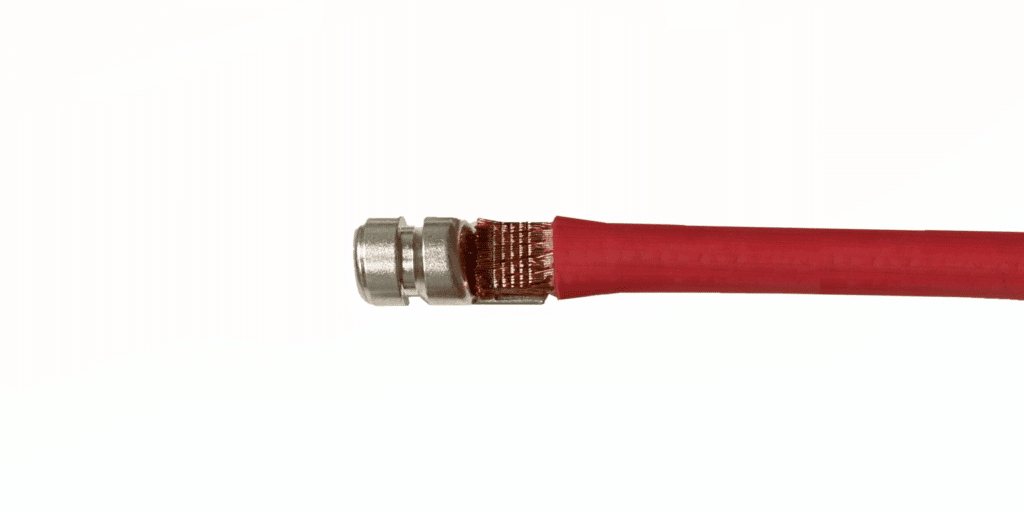

High Voltage Cable Termination: 35mm2 Cable Termination

The emergence of EV Vehicles has many profound benefits such as the elimination of the carbon footprint, no need for gasoline, and lower maintenance costs. However, electric vehicles have longer charge times compared to refueling a combustion engine. To decrease battery charging time while increasing the power provided to the motors, the industry is increasing the voltage levels of their systems, which overcomes the losses associated with higher current levels. That is why high voltage cables are required to increase voltage to the battery to counteract long charging times.

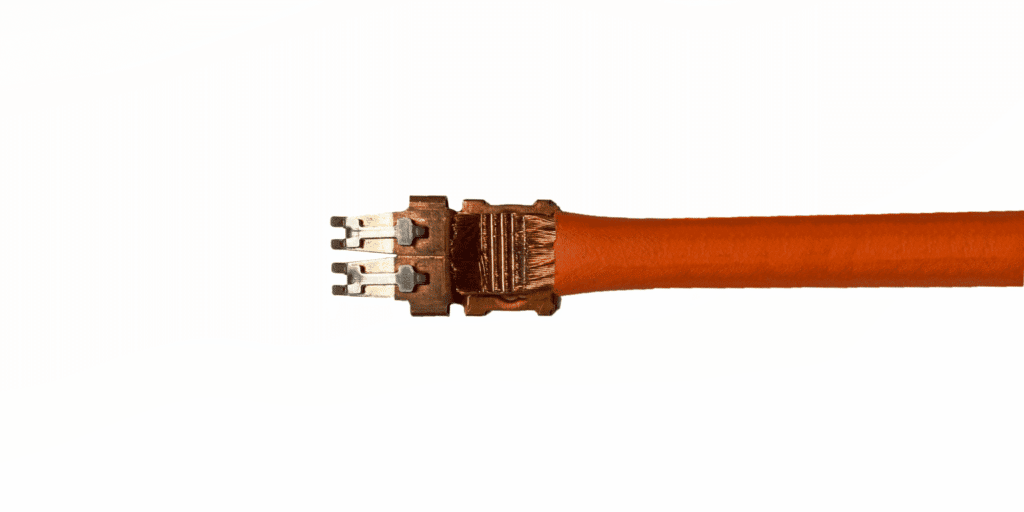

USCAR-38 defines test methods and performance criteria for evaluated ultrasonically welded wire-to-terminal metallurgical bonds. This test specification is intended to evaluate the strength and performance of the interface between wires to an electrical terminal. With the growing market of EV Vehicles, quality control for HV cable termination is becoming more important to ensure the functionality of the electrical components in EV vehicles. In compliance with USCAR-38, the US-3620STH large cable termination machine has the ability to detect 5% of missing strands of total cross section area.

CLC Advantages for High Voltage Cable Welding

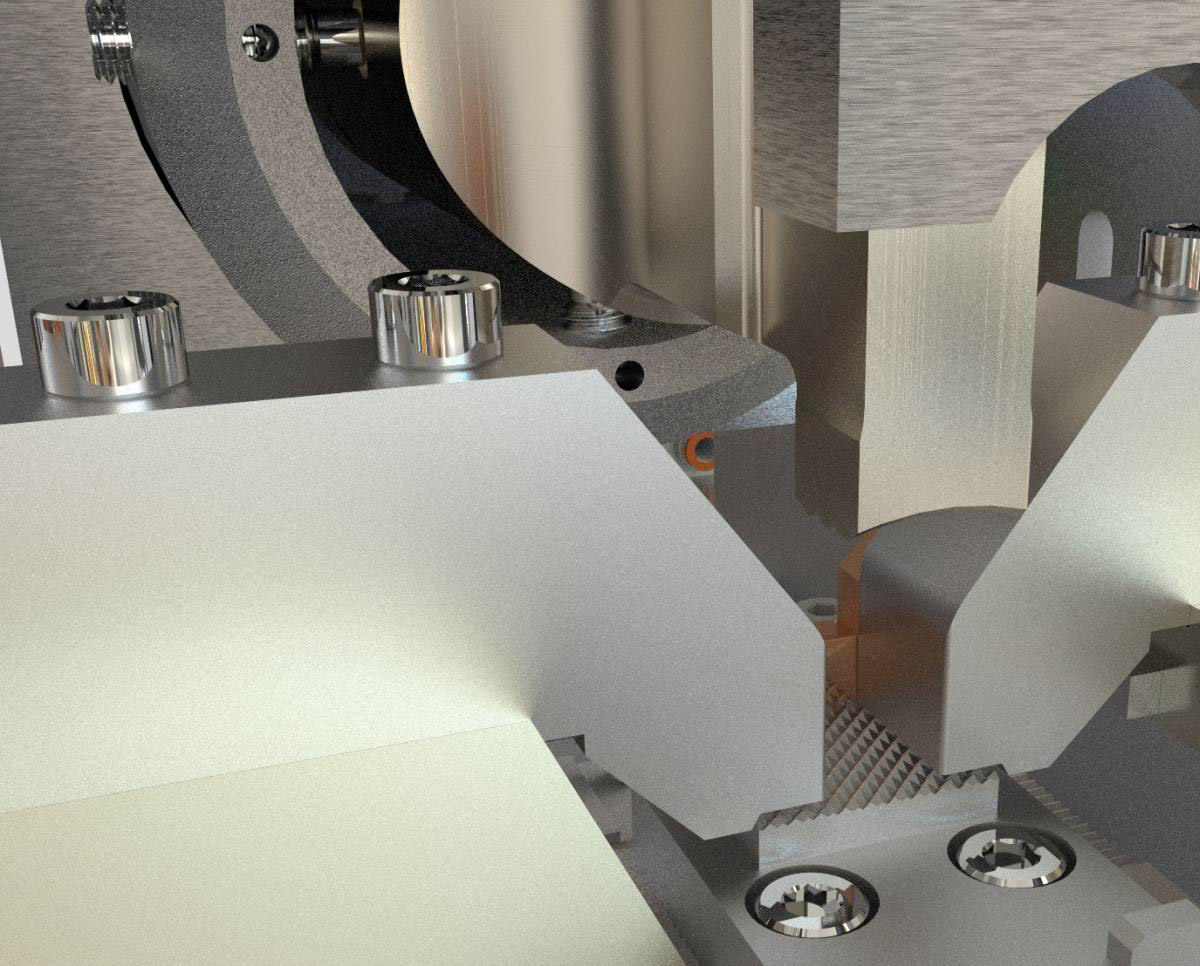

TECH-SONIC’s patented servo control HV cable welding machine for large cables has a unique process (Multi-step process) which allows the user to apply the proper amount of force and energy to the weld at the appropriate time. By being able to control specific welding parameters such as time, energy, force, and amplitude, it enables the users to create precise, consistent, and repeatable welds. The US-3620STH has the capability to apply 5000N of force and the ability to weld 50mm2 of wire to a terminal for optimal results.

Features and Benefits of Closed Loop Control Technology for High Voltage Cables

- In compliance with USCAR-38, ability to detect 5% of missing strands

- Ability to weld up to 35mm2 copper cable and up to 60mm2 aluminum cable

- Capability of over 20 weld steps

- Ability to change and adjust force and amplitude during weld cycle

- Measurement of pre-weld and post-weld height

- Lower energy/ lower operational cost

- Longer tooling life due to “patented” servo control technology