EV Battery Innovation: The Race to Electric Car Supremacy

The demand for electric vehicles (EVs) is increasing. Although this is only a fraction of gasoline-powered vehicles, it still sums up to millions worldwide. The global sales for electric vehicles have reached around 60% per year, reaching 2.1 million in 2018.

Electric Vehicle Market Growth

Electric vehicles (EVs) market growth performance depends on the region. But with stricter CO2-emission regulation, electric vehicle sales are expected to rise. The US market has increased due to the growing popularity of Tesla electric vehicles. These are selling almost as well as other gasoline-powered vehicles.

But this trend might be derailed if the production of EV batteries does not scale up. Aside from the negative impact of the coronavirus pandemic, prices for the EV batteries’ basic ingredients are also rising.

This is because of the increasing demand for EVs, and as a result, EV batteries. Manufacturers are scrambling for these raw materials to assure a continuous supply chain for the coming months.

The lithium-ion battery is one of the most popular types in recent years, and it still has a lot to offer. Read the article on Recent Advances in Welding EV Batteries.

Electric Vehicles

Electric vehicles operate on one or more electric motors powered by rechargeable batteries. Also known as electric cars, EVs have lower maintenance costs and are eco-friendly. Since they are powered by electricity, they have fewer moving parts compared to combustion-engine vehicles.

They have lower emissions so they do not significantly contribute to air pollution. This is especially true when using renewable power such as wind to charge the EVs. The emissions are further lowered, diminishing environmental damage.

However, the drawback of using electric vehicles will continue unless EV battery innovation takes place. Researchers are trying to maximize the EV’s range, and shorten EV batteries charging time. The need to reinvent EV batteries is imperative. One solution is building a “solid-state battery” to slash dendrite formation.

And so the race to build better batteries for electric vehicles EV is on. Consumers look for electric cars that are sleeker, faster, and with more range on a single charge. One that is less expensive but has a higher performance.

EV Battery Innovation

Batteries are the “heart” of electric vehicles. And developing new technology is crucial to creating a more high-performing one. This requires a good strategy to meet the demand for more efficient EV batteries.

Scientists have now developed a rechargeable lithium battery with an extended driving range. Unfortunately, lithium shortens the battery’s life by forming dendrites. These are found on the lithium anode after several charging cycles. It degrades the EV battery’s performance, and may even short-circuit it.

Fortunately, Harvard engineers have developed a solid-state lithium battery that charges faster, and that could last the EV Battery lifetime. Scaling it up for commercial production will be the real challenge. But, this is still up for grabs.

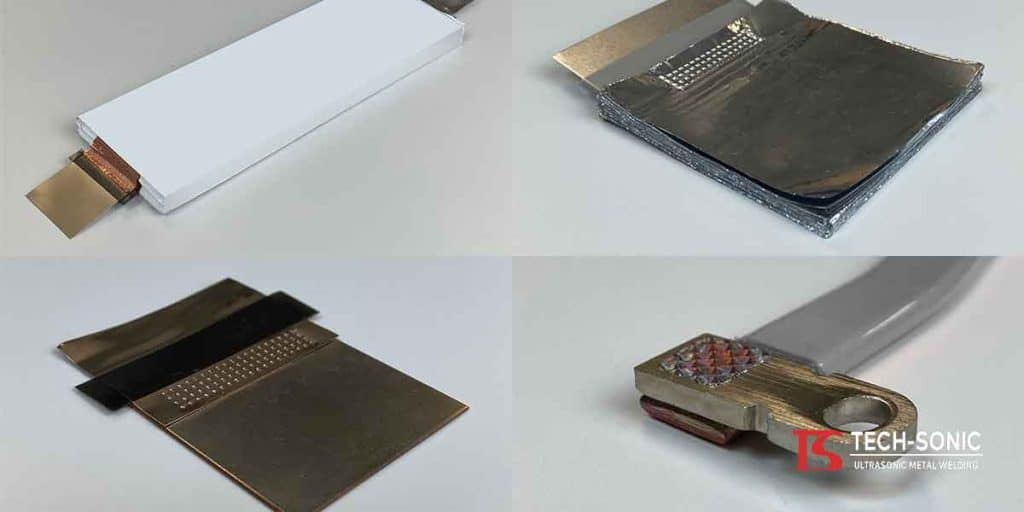

In the meantime, manufacturers have to maximize speed, and efficiency to win the race to build better batteries for electric vehicles EV. In connection with this, TECH-SONIC has devoted its research and development to “CLC” or Closed Loop Control ultrasonic metal welding in recent years.

This technology is particularly useful in spot welders for EV battery assembly. It combines the latest technologies in ultrasonic welding, servo control, user-friendly microprocessor control, and load cell force feedback. This results in a 100% digital welding process.

TECH-SONIC, Inc. has developed a heavy-duty welding machine, the US-3620SH ultrasonic spot welding machine for larger stacks of foils, tabs, and busbar welding applications. Its control and efficiency allow users to increase their capabilities without increasing power requirements. This is recommended for manufacturers who seek high productivity and precision in welding.

Featured Products

CLC Pouch/Prismatic Battery Welder

US-3620SH

CLC Cylindrical Battery Welder

US-935SH