TECH-SONIC Ultrasonic wire splicers meet industry standard

- TECH-SONIC

- November 12, 2025

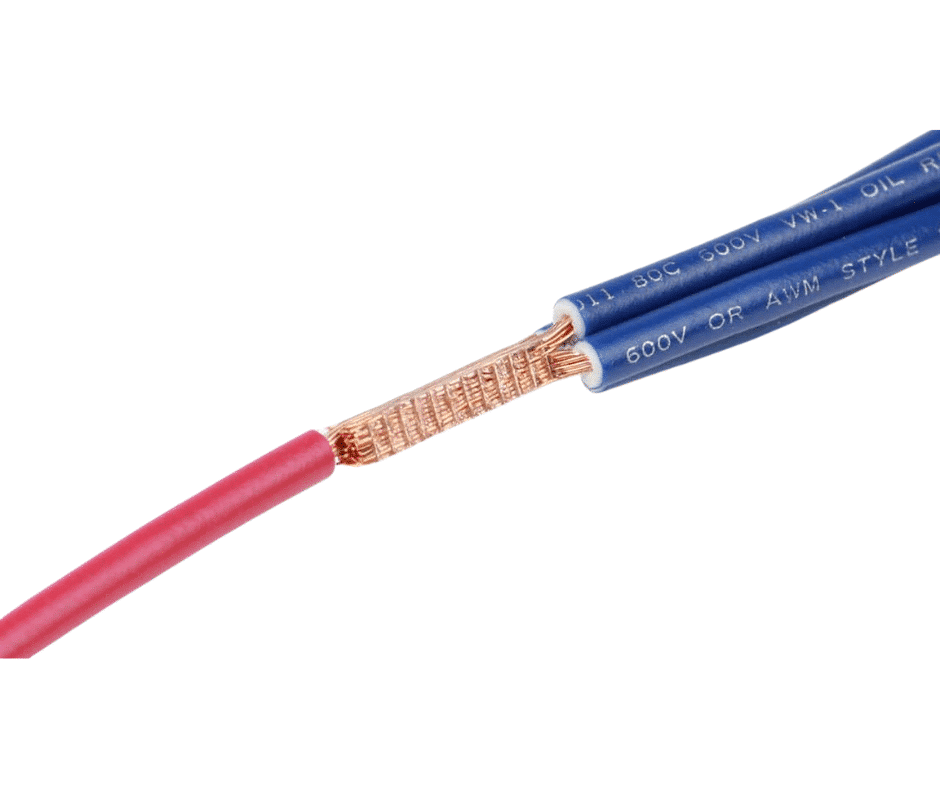

The market for wire splicers is competitive and diverse. This is due to the industry’s constant demand for reliable and efficient wire joining. In the US, where aerospace, automotive, household appliance, military, EV battery, health and communications industries thrive, there are several players involved in the wire splicer supply chain.

However, with innumerable choices across the market, it becomes crucial for interested buyers to understand the nuances of wire splicers and find the right supplier. And this is where Tech-Sonic’s experience in supplying ultrasonic wire splicing machines deserves special mention. We deliver customized, innovative and value-driven wire splicing solutions “states John Hall, Director of Marketing for TECH-SONIC”. Our global expertise in this field has helped us maintain leadership across the market.

How Our Efficient Wire Splicers Help Create High Quality Welds?

Ultrasonic metal welding involves joining several wires together or joining wires with conductive contacts or terminals to create wire harnesses for different industries, like automotive, specifically EV battery manufacturing and telecommunications. Benefits of the process include:

- Superior quality weld joints ensure durability of wire harnesses.

- Low energy consumption

- Improved process control

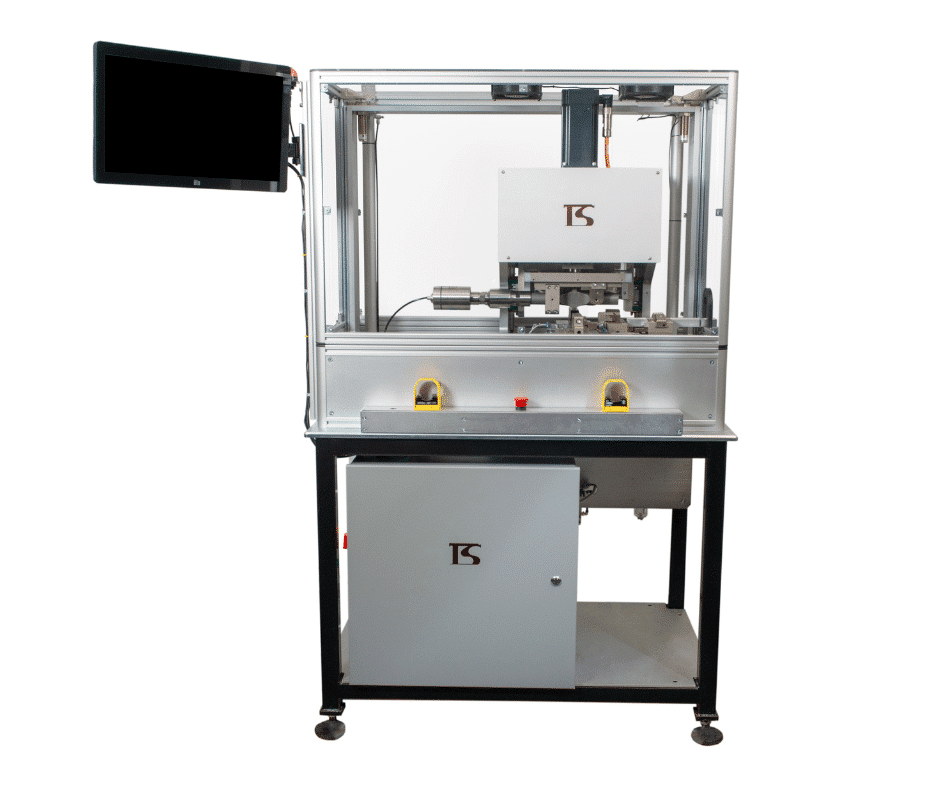

If you want to make the most of ultrasonic metal welding, we have several options available.those models included are US-3020WS2P, which is our servo driven system, our TS-20W PLUS and our TS-20W ultrasonic wire splicers. Our machines create strong, solid-state and clean molecular bonds with high electrical conductivity.

Exclusive Attributes of Our Ultrasonic TS-20W Plus Wire Splicer

At Tech-Sonic, we provide Pneumatic and CLC wire splicing machines, specifically designed for superior joint quality, enhanced reliability, improved process control, high productivity and precision welding. Major attributes of our ultrasonic TS-20W PLUSWire Splicer, includes:

- Offers entry-level welding experience for all kinds of customers.

- Low-maintenance and user-friendly ultrasonic welding for several markets with low tooling cost.

- Features in-built touchscreen monitor.

- Ability to weld cross-section areas ranging from 0.36 square mm to 32 square mm.

- Precise measurement of pre-weld and post weld height.

- Avoids the use of outside consumables in soldering and crimping procedures.

- Helps produce strong joints with high electrical and thermal conductivity.

- Ultrasonic output and consistent measurement help produce high cPk values.

- Tooling can last for more than 1 million cycles with small wire cross-sections.

With such amazing features and benefits of our TS-20W PLUS wire splicer, companies across varied industries can rest assured about the superior quality, reliability and precise completion of their most important projects on time. We provide the best splicing machine for joining non-ferrous metals without the use of heat, connectors or consumables.

FAQs

- What are the different wire harness applications served by your products?

We provide solutions for a diverse range of wire harness applications including wire splicers, ring terminators, cable terminators and MAK terminators.

- What are the advantages of practicing ultrasonic welding with wire splicers?

Ultrasonic welding becomes a highly reliable and exclusive procedure.

Key benefits of the process include:

- Reduced manufacturing cost, energy and time.

- Improved process control

- Top quality weld

- What is the Closed-Loop Control technology feature in your Servo wire splicer?

Closed-Loop control technology in our US-3020WS2P wire splicer helps detect missing strands more consistently and accurately than ultrasonic TS-20W pneumatic wire splicers. The technology uses force feedback to detect missing strands below 3% of the total cross section.

Related Topics:

Featured Products

CLC Busbar Termination Welder

US-6020FWB

CLC Large Cable Termination Welder

US-3620STH