Wiring Termination Solution

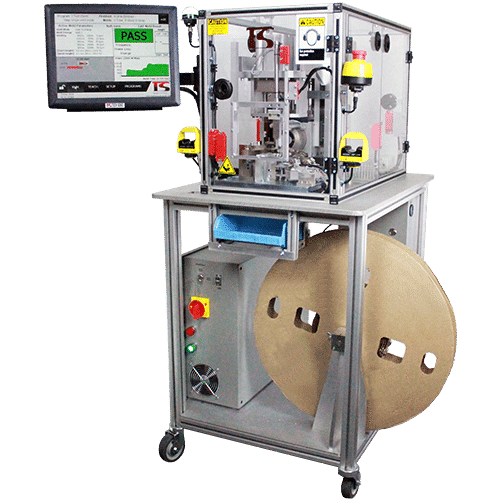

Conduction is a growing concern for many EV manufacturers in today’s competitive landscape. In order for EV’s to function properly, effective low resistance wire bonding is required. Ultrasonic welding is the ideal joining process for joining wires, efficiently producing low-resistance bonds. TECH-SONIC’s patent-pending closed-loop control ultrasonic wiring termination machine, model US-3620MAK-S, provides a new ultrasonic metal welding capability beyond conventional ultrasonic metal welders. It bonds single point ground terminals and can accommodate a variety of terminals by changing terminal nest hardware. It uses a microprocessor-controlled ultrasonic welder and servo-controlled spot welding hardware that can weld multiple wires onto a single terminal and provide a stress-free joint. In compliance with USCAR-38, it has the ability to detect 3% of total CSA.

The US-3620MAK-S wiring termination machine also features industry-leading missing wire and strand detection. A typical pneumatic termination machine can only detect missing wires if they are greater than 5% of the total cross section of wires. The US-3620MAK-S ultrasonic wiring termination machine can detect missing wires less than 3% of the total cross section and can detect the loss of a single 0.35mm² wire, which is commonly retracted from the weld area without the user’s awareness. Many automobile manufacturers require the wire harness producers to detect less than 3% of missing wires and have determined that the limitations of the pneumatic process prevent them from providing consistently acceptable part quality.

CLC Advantages for Wiring Termination

Features and Benefits of Closed Loop Control Technology for Wire Termination

- In compliance with USCAR-38, ability to detect single missing wire at 0.35mm2 or 3% total CSA

- Detects retracted wires from weld area, and added insulation into the weld area

- Multi-step welds with controlled force and amplitude parameters

- Permits up to 20 weld steps

- Produces single point ground terminals and can accommodate a variety of terminals by changing terminal nest hardware

- Uses microprocessor controlled ultrasonic welder that can weld multiple wires onto a single terminal and provide stress free, low resistance joint

- 22 inch touchscreen display

- Cross section up to 36mm2

For more technical information, please download our brochure.

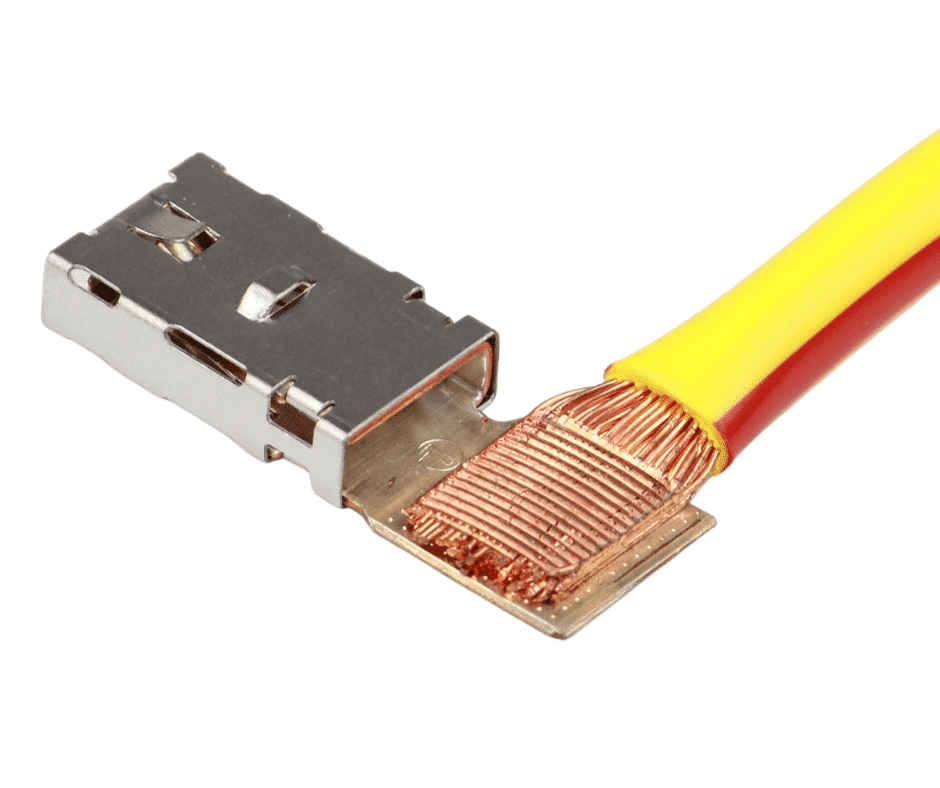

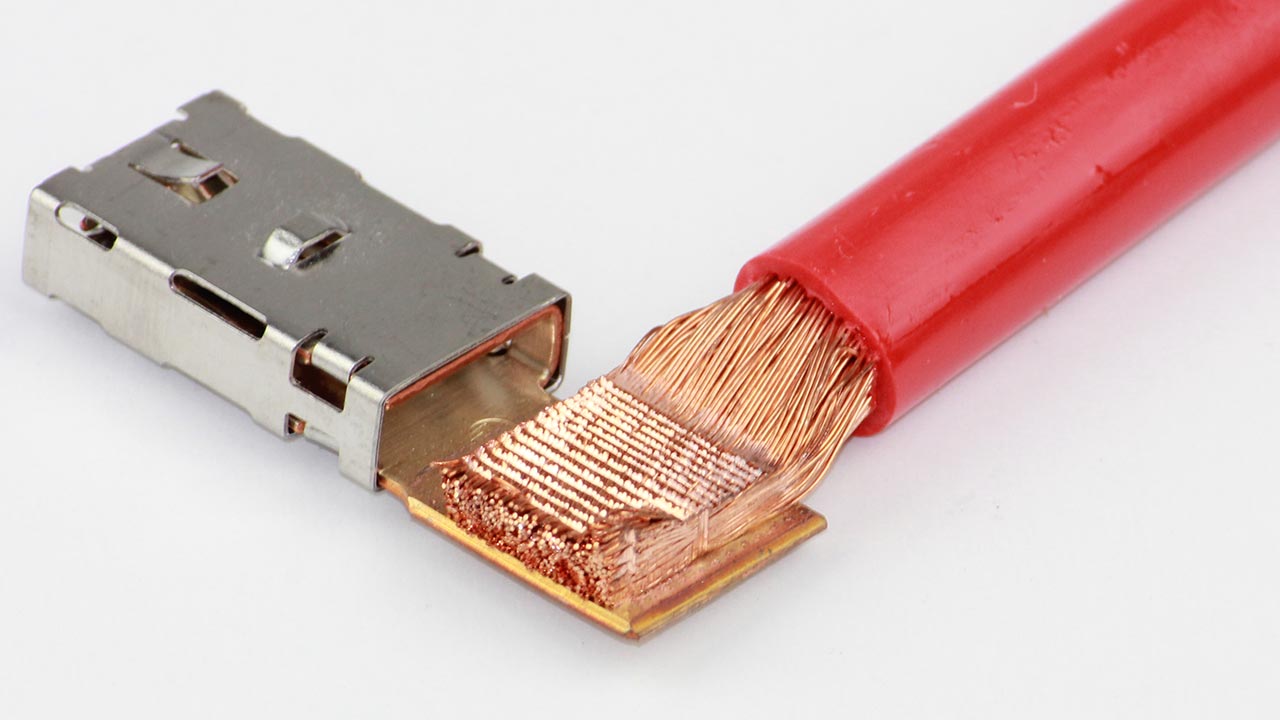

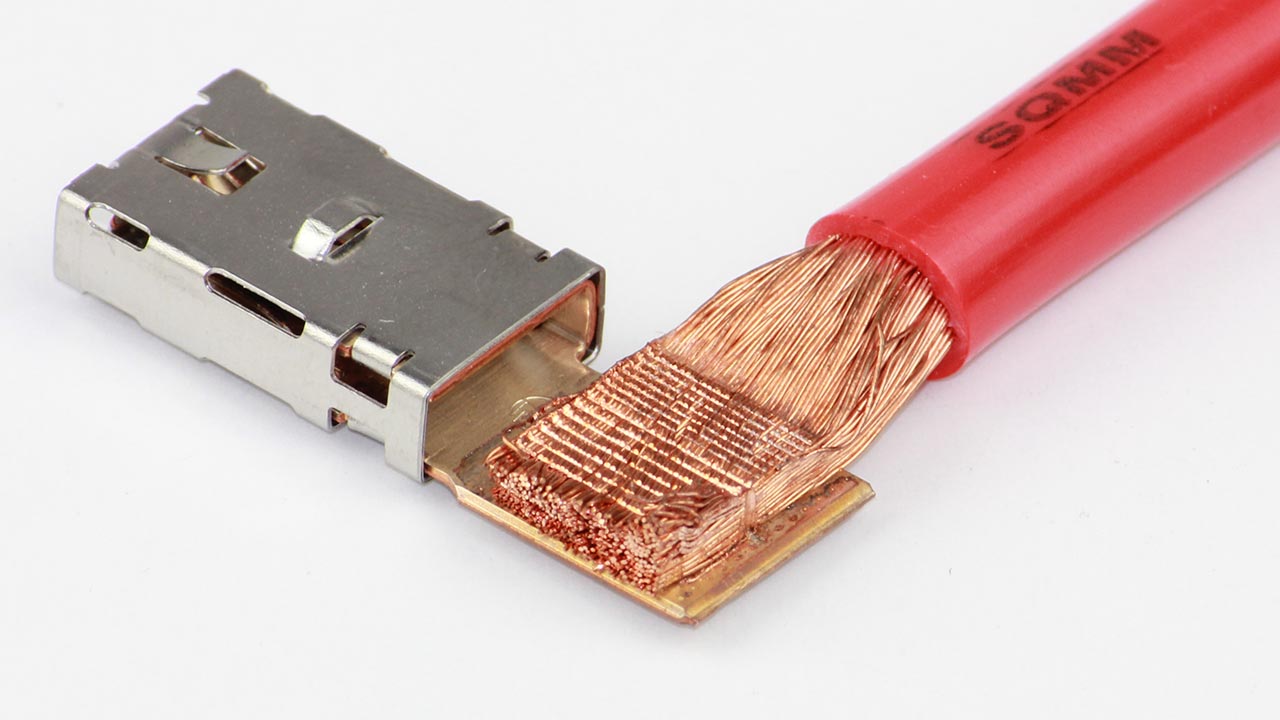

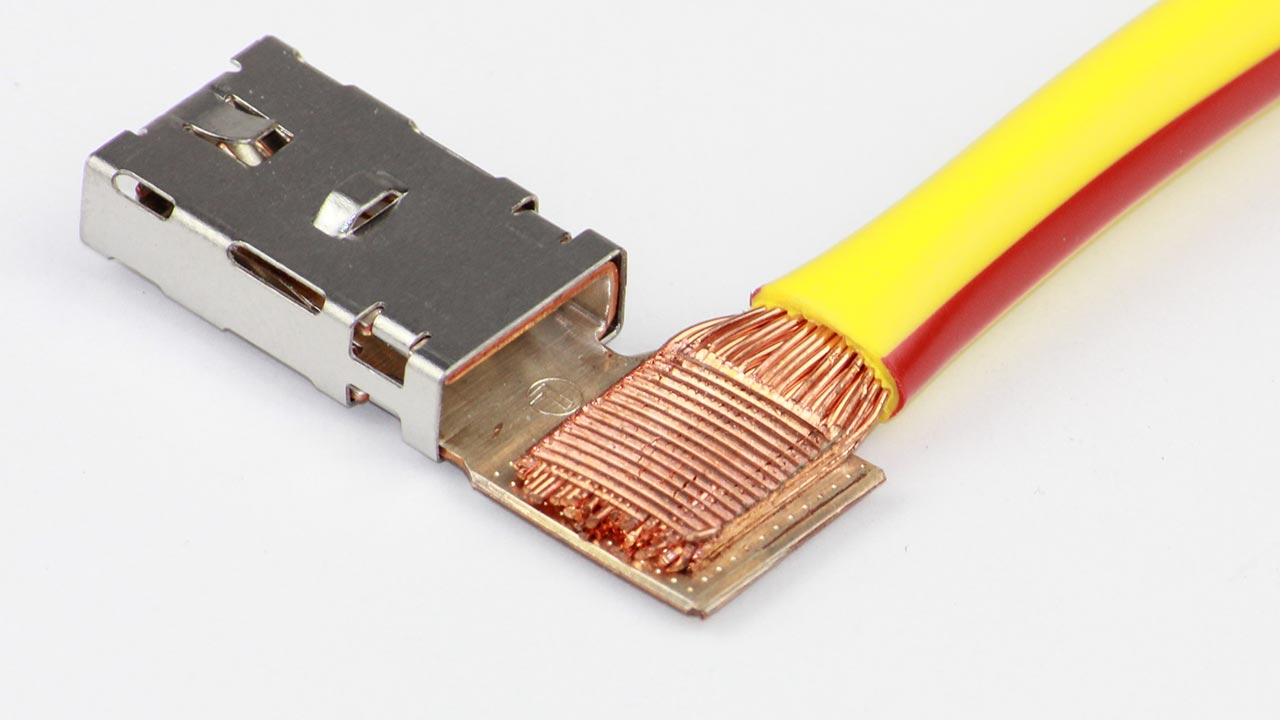

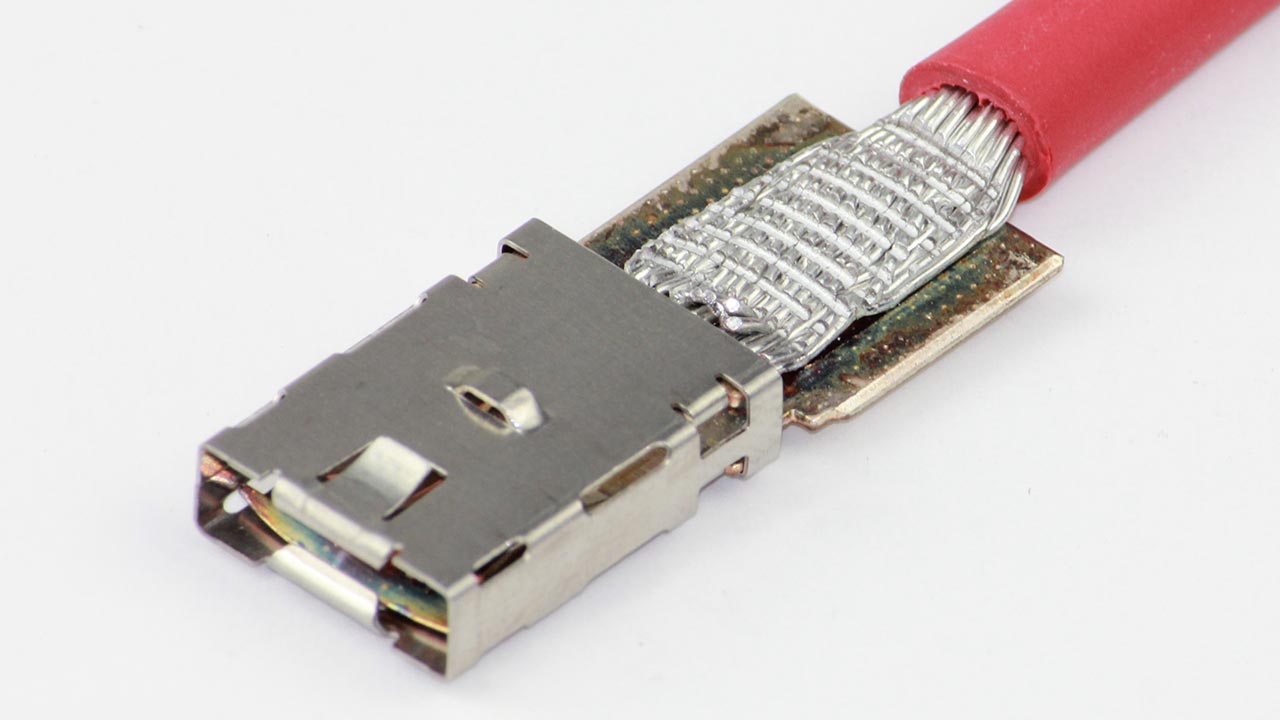

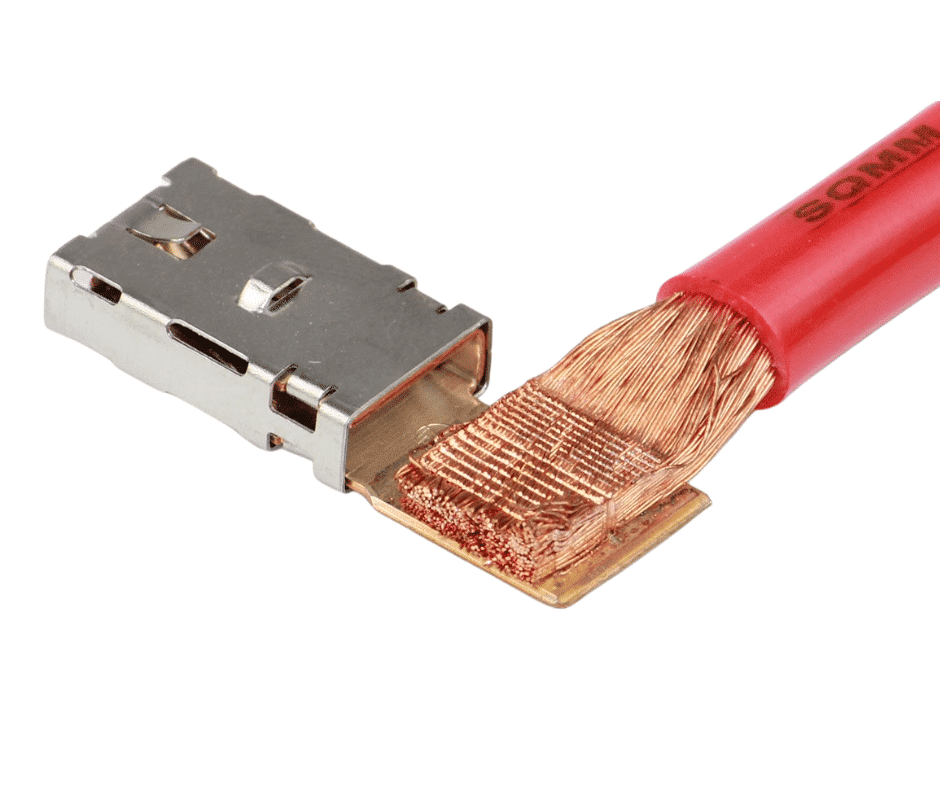

US-3620MAK-S SAMPLES

Related Products

CLC Ultrasonic Wire Splicing Machine

US-3620WS2P

CLC Ultrasonic Ring Termination Welder

US-3620SRT

CLC Large Cable Termination Welder

US-3620STH