Busbar Welding of Electric Vehicle Batteries Using Ultrasonic Welding

As the market for electric vehicles continues to expand, manufacturers will seek solutions to improve current technological processes for electric vehicles when it comes to battery performance such as efficiency, battery lifespan, and charging time. To maximize these key potential factors, ultrasonic welding will play a crucial part in these technological breakthroughs. Since the 1980s, the automotive wire harness manufacturing industry has been documented as the largest user of ultrasonic welding.

In EVs, large banks of battery cells are fused in sealed packs to achieve the required operating voltage and current to power a vehicle’s electric motor. Two main concerns regarding EVs are power storage and driving range.

OEM’s are addressing these issues in two ways:

- Creating larger batteries that allow for greater range

- Creating more powerful batteries that allow for faster charging.

What are the benefits of busbar welding in Electric Vehicle batteries?

With the development of electric vehicles, manufacturers have found that busbar welding is the ideal solution to improve conduction in EVs. Busbars are flattened conductors that are revolutionizing the EV landscape, which are housed inside switchgears, panel boards, and busway enclosures for local high current power distribution. A busbar is a metallic strip or bar made from copper, brass, or aluminum that grounds and conducts electricity.

The following are benefits of using busbars in EVs:

- Ability to add or relocate power easily without any downtime

- Requires no routine maintenance

- Faster and less costly for expansion or remodeling

- More environmentally friendly as it requires fewer installation materials

- Flat conductor takes up less space

- Can support up to 15% more power than cable,

- Less weight and packaging space with much better flexibility,

- More efficient heat dissipation than stranded cables

Busbar Welding Using Ultrasonic Welding Technology

With the implementation of busbars in EVs, a sensitive and solid joining procedure is needed to ensure conductivity. Ultrasonic welding technology is a proven joining process that is ideal as specified by carmakers for use in busbars and power electronics. With ultrasonic welding, parameters can be controlled and there is less stress on the weld which makes the welds repeatable and precise. Ultrasonic welding is the preferred joining process for busbars.

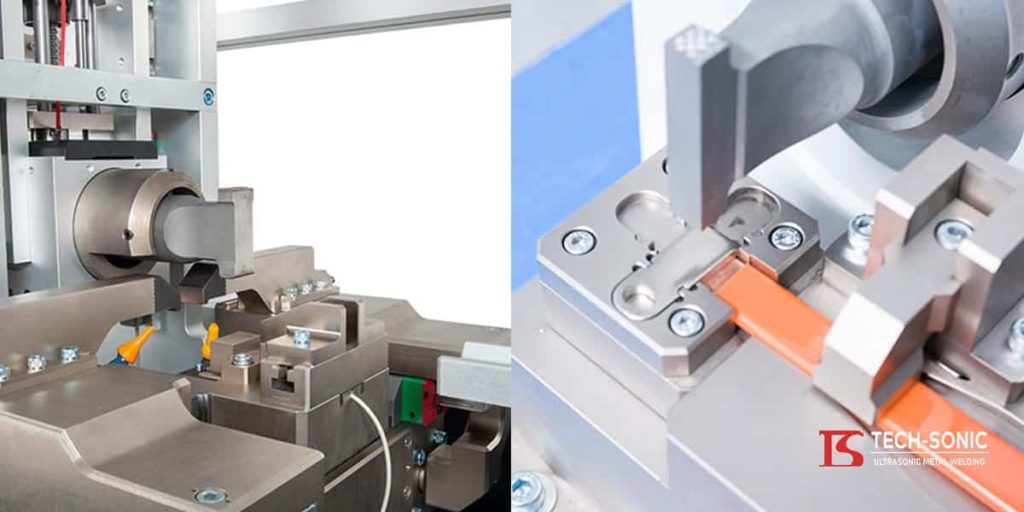

However, TECH-SONIC has developed a state-of-the-art ultrasonic joining process called “CLC” or Closed Loop Control. Conventional ultrasonic welding operates on a pneumatic cylinder which can have some inconsistencies with the air variation, but TECH-SONIC’s Closed Loop Control ultrasonic welding uses an electric servo motor and load cells in conjunction with an ultrasonic welder. This integration allows users to control and monitor the applied force and amplitude during the weld process.

TECH-SONIC calls this process “multi-step welding”, turning a once open loop system into a closed loop system. This technology provides superior quality control with highly repeatable welding results, creating significant cost savings. This is the ideal joining process for busbars to ensure a conductive and solid weld.

The busbar termination machine from TECH-SONIC is widely used in electrical components to distribute power from a main power source. Instead of the standard single step, this busbar welding machine allows for up to 20 weld steps with less defects and superior quality welds.

Related Posts: