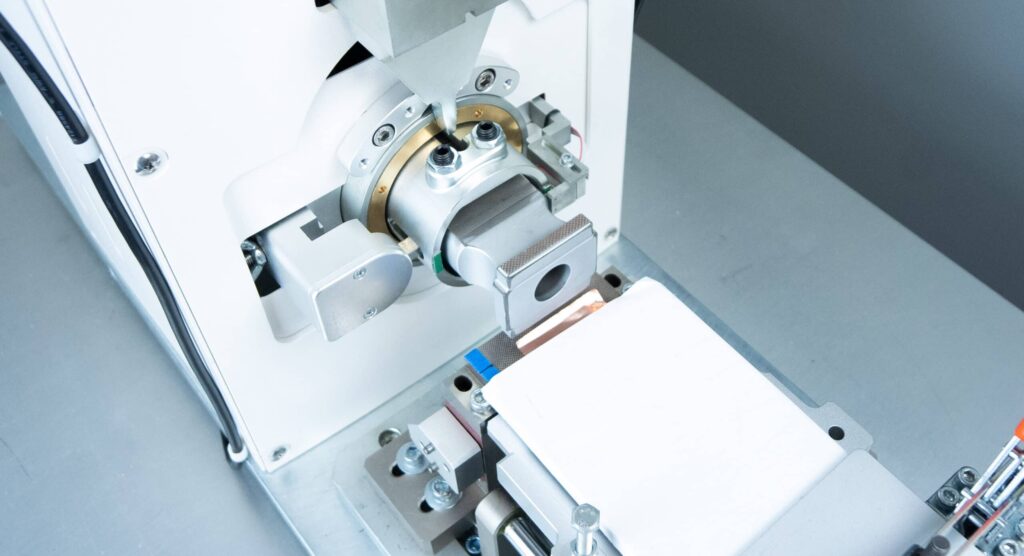

US-3620SH with Table Mount

Ultrasonic Spot Welding Machine for Prismatic and Pouch Battery

As the production of EVs continues to grow, the need for precise welding of pouch and prismatic battery cells is becoming increasingly critical. Lithium pouch and prismatic cells consist of stacked layers of anodes, separators, and cathodes fused in between layers of laminated film. These types of cell applications can be created in custom sizes and shapes. Cells are then connected in a series and parallel to acquire the desired voltage and capacity. To accurately weld the foil stacks used in each pouch and prismatic cell application for EV batteries, advanced ultrasonic welding technology featuring Closed-Loop Control of servo-driven weld heads is the solution.

With a single-micron resolution linear encoder, the US-3620SH ultrasonic spot welding machine is able to detect weld height changes relative to a set tolerance window with greater precision and accuracy than their pneumatic counterparts. It can detect one single missing or added foil in a stack of eighty (the thickness of a foil is around 10um), then signal the error to the user before initiating the welding sequence. Typical pneumatic ultrasonic spot welding machines do not have missing or added foil detection capability with such precision. By compressing the foils, the US-3620SH ultrasonic spot welding machine can reduce or prevent foil breaks. It also prevents cracks by reducing stress and allows no coating damage by ultrasonic vibration. In the pneumatic processes, the top layers of foils are often cracked by the violent descent of the horn.

CLC Advantages for Pouch and Prismatic Battery Welding

TECH-SONIC’s US-3620SH ultrasonic spot welding machine allows the user to apply the proper amount of force and energy to the weld at the appropriate time. By being able to control these specific welding parameters, it enables the users to create precise, consistent, and repeatable welds (Multi-Step).

Features and Benefits of CLC Technology for Pouch and Prismatic Battery Welding

- Can detect one single missing or added foil in stack of eighty (foil thickness is around 10um)

- Ability to change and adjust force and amplitude during weld cycle

- Direct-drive servo provides the ability to weld thicker stacks to busbar, utilizing a wider horn

- Capability of over 20 weld steps

- Capability to reduce excess stress on foils and tabs by using ideal welding parameters

- Soft touch landing on weld materials controlled by servo

- Less power/ lower operational costs

- Longer tooling life due to servo control “patented” technology

- Self Leveling Mechanism

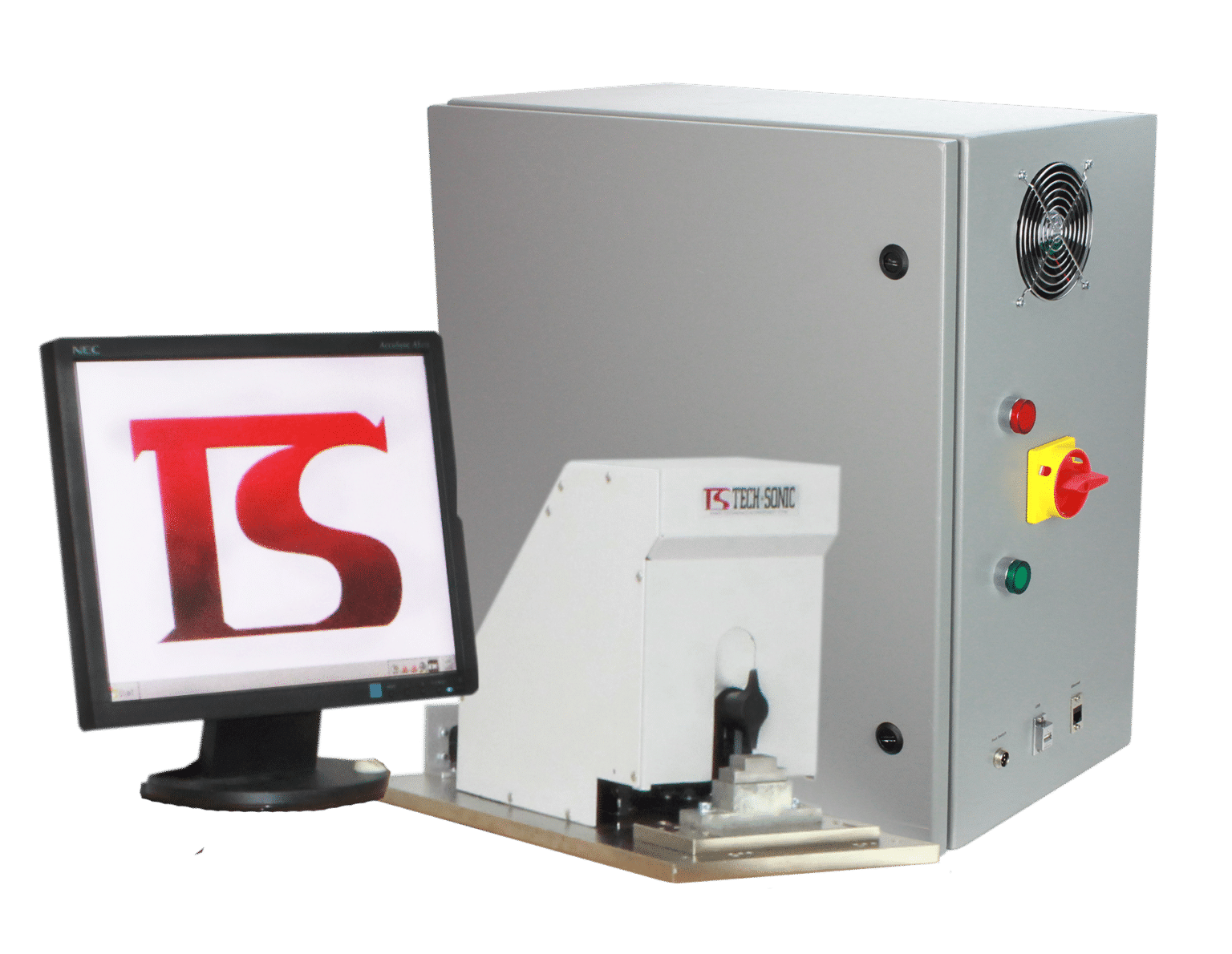

US-3620SH Standard without Table Mount

For more technical information, please download our brochure.

Related Products

CLC Cylindrical Battery Welder

US-935SH

CLC Pouch/Prismatic Battery Welder

US-5020SH