High Voltage Cable Termination: EV Charging Solution

As the electric vehicle (EV) industry grows and diversifies, the larger batteries are required to provide longer driving range. To decrease battery charging time, the industry is increasing the voltage levels of their systems, which overcomes the losses associated with higher current levels. Voltage levels of up to 1000V are needed to provide adequate power to run the vehicle. The joining process is called high voltage cable welding.

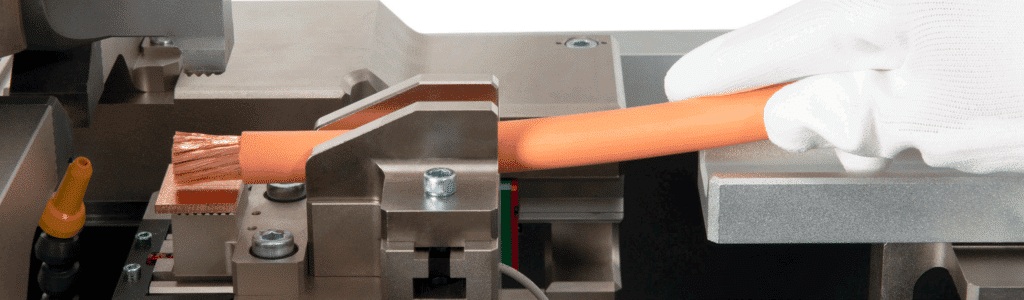

To minimize power loss, high voltage cables need to be welded to each other. Due to the high currents that need to pass through these connections, ultrasonic cable welding becomes the ideal bonding process due to the solid state welding which results in no resistance. The true solid-state metallurgical bond created by ultrasonic welding will reduce the resistance in the connection and, consequently, the power loss and generate no temperature in the welding joint. To address high voltage cable termination, the use of ultrasonic multi-step welding such as that leveraged by closed loop control (CLC) technology can be the solution.

CLC Advantages for High Voltage Cable

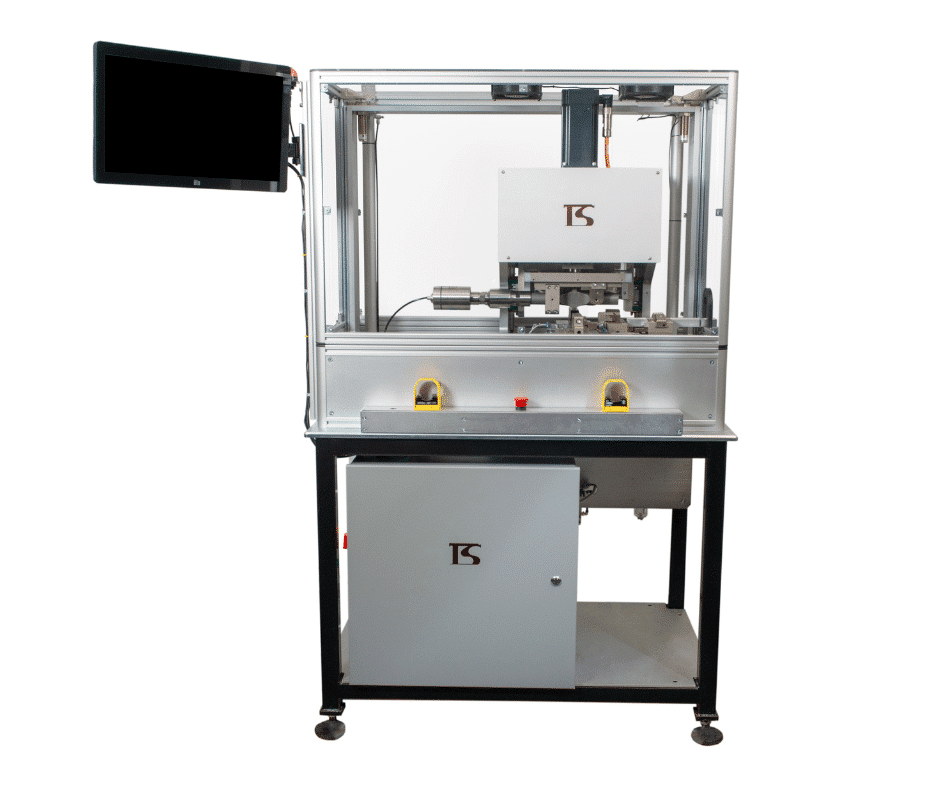

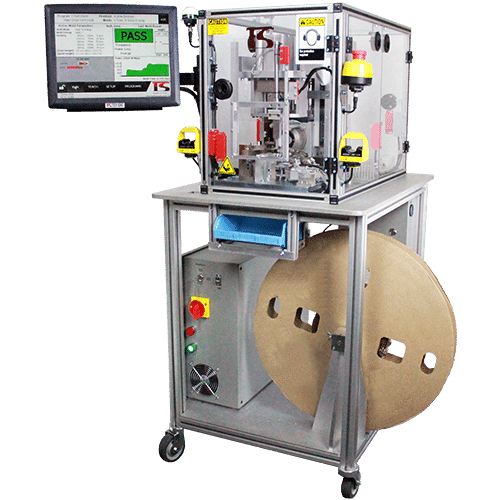

TECH-SONIC’s patented servo control HV cable welding machine for large cables has a unique process (Multi-step process) which allows the user to apply the proper amount of force and energy to the weld at the appropriate time. By being able to control specific welding parameters such as time, energy, force, and amplitude, it enables the users to create precise, consistent, and repeatable welds.

Features and Benefits of Closed Loop Control Technology for High Voltage Cables

- In compliance to USCAR-38 requirements, ability to detect as low as 5% of missing strands

- Welding range: 30mm2 up to 95mm2 copper wire with 6 KW power

- Welding range: 30mm2 up to 120mm2 aluminum wire with 6 KW power

- Less power/ lower operational cost

- Longer tooling life due to servo control “patented” technology

- Measurement of pre-weld and post-weld height in micron, force in 0.1N, and energy 0.1 J (CLQC)

- Windows 10 Operating System

For more technical information, please download our brochure.

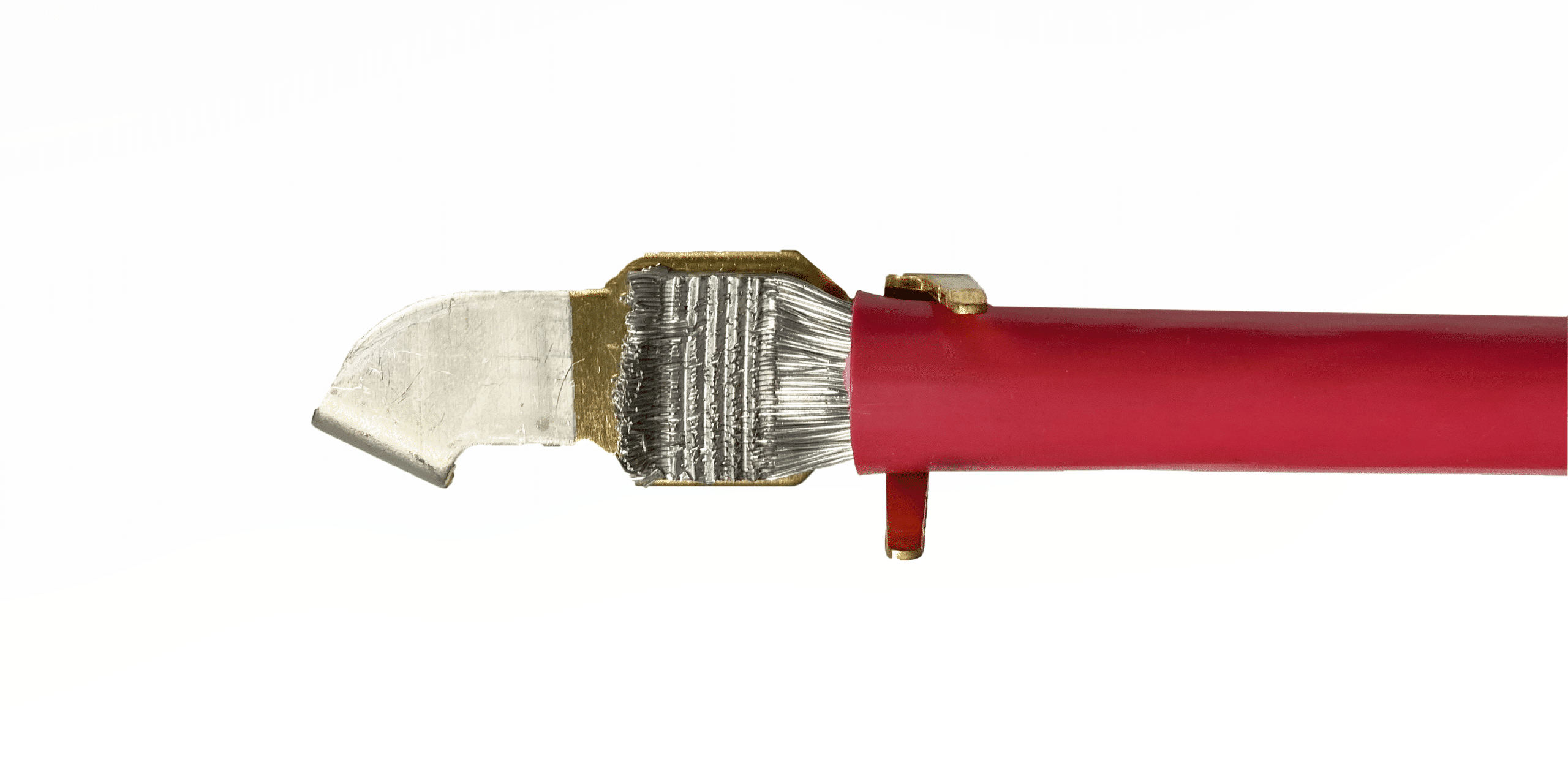

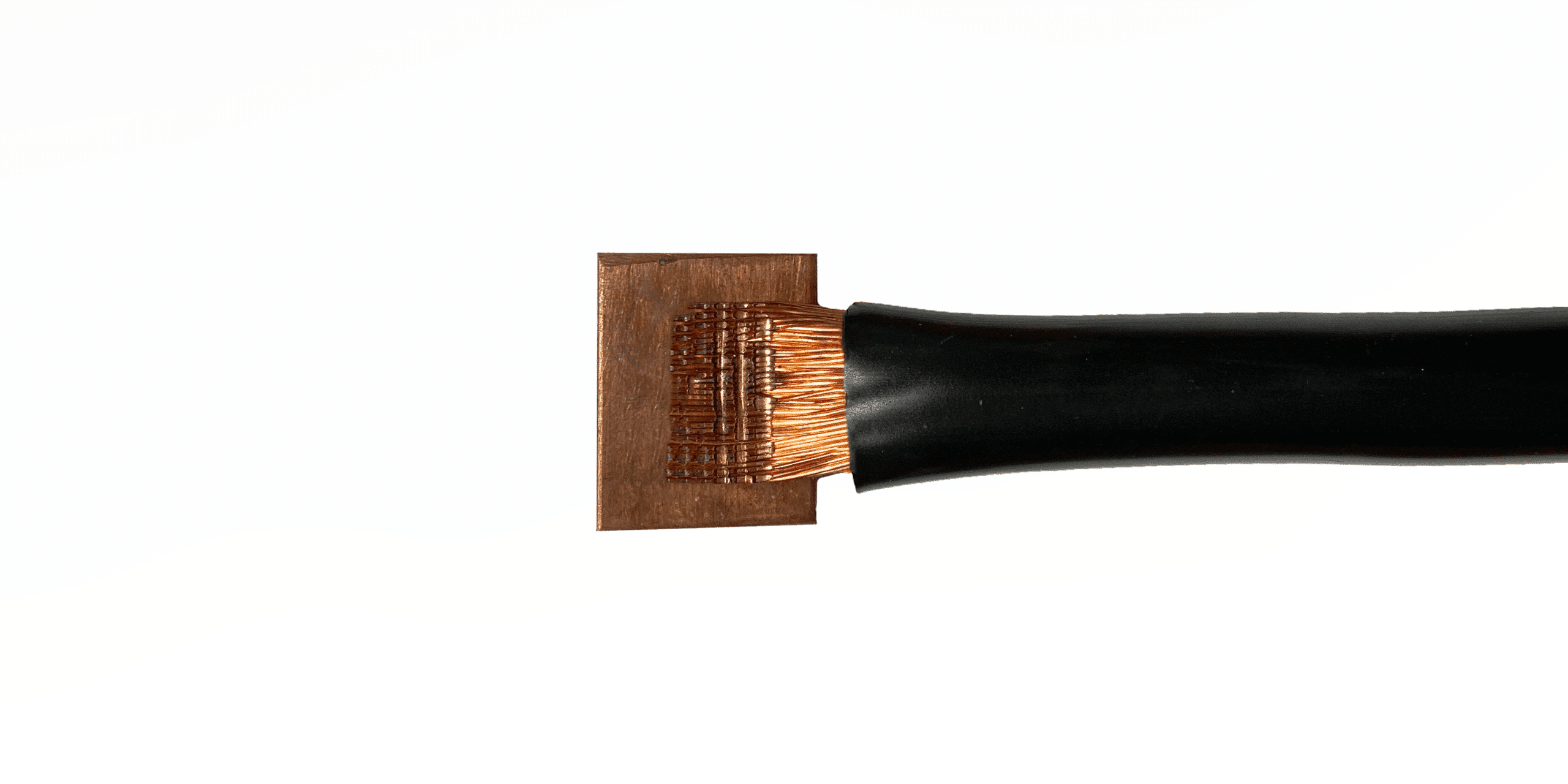

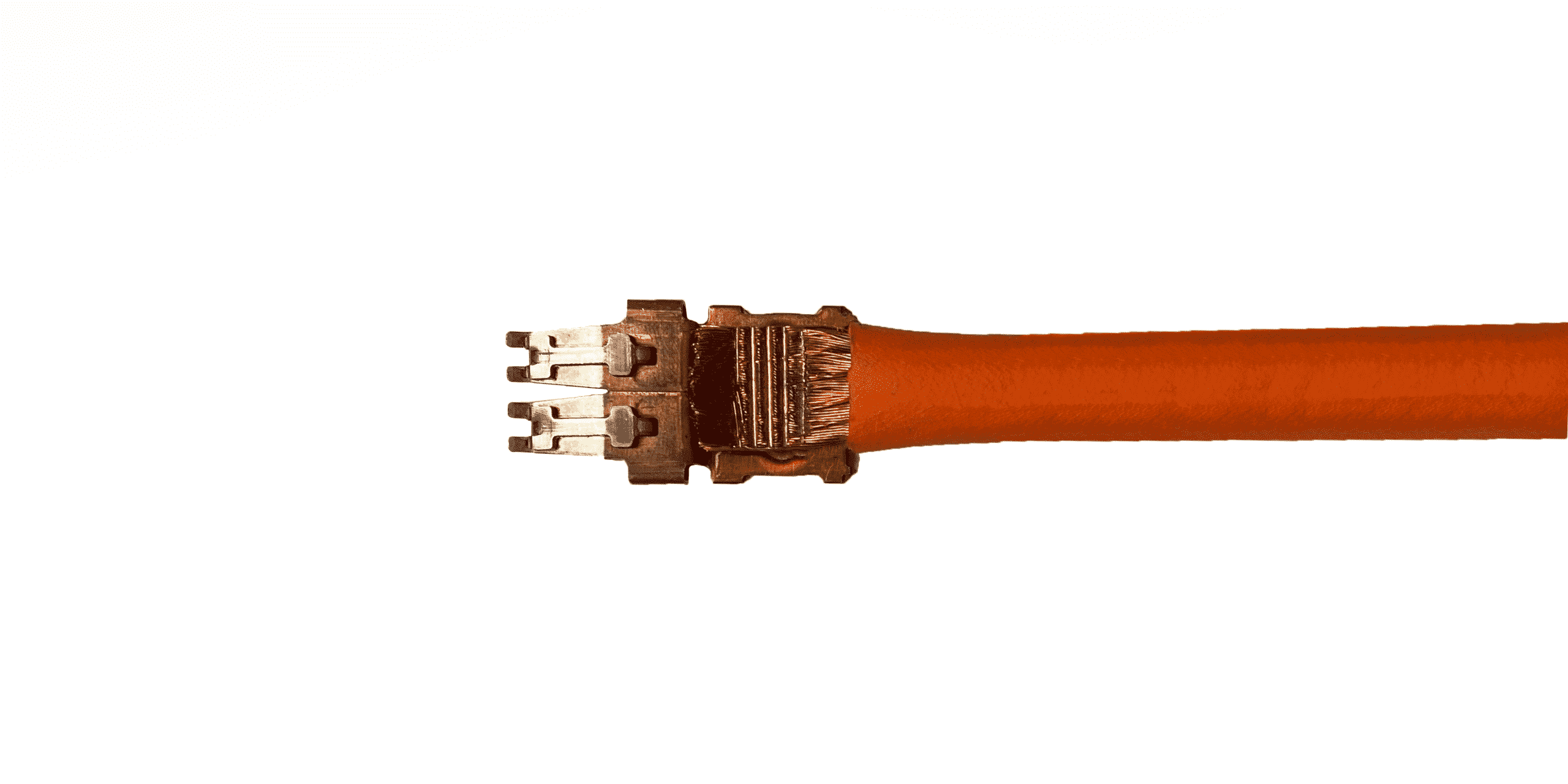

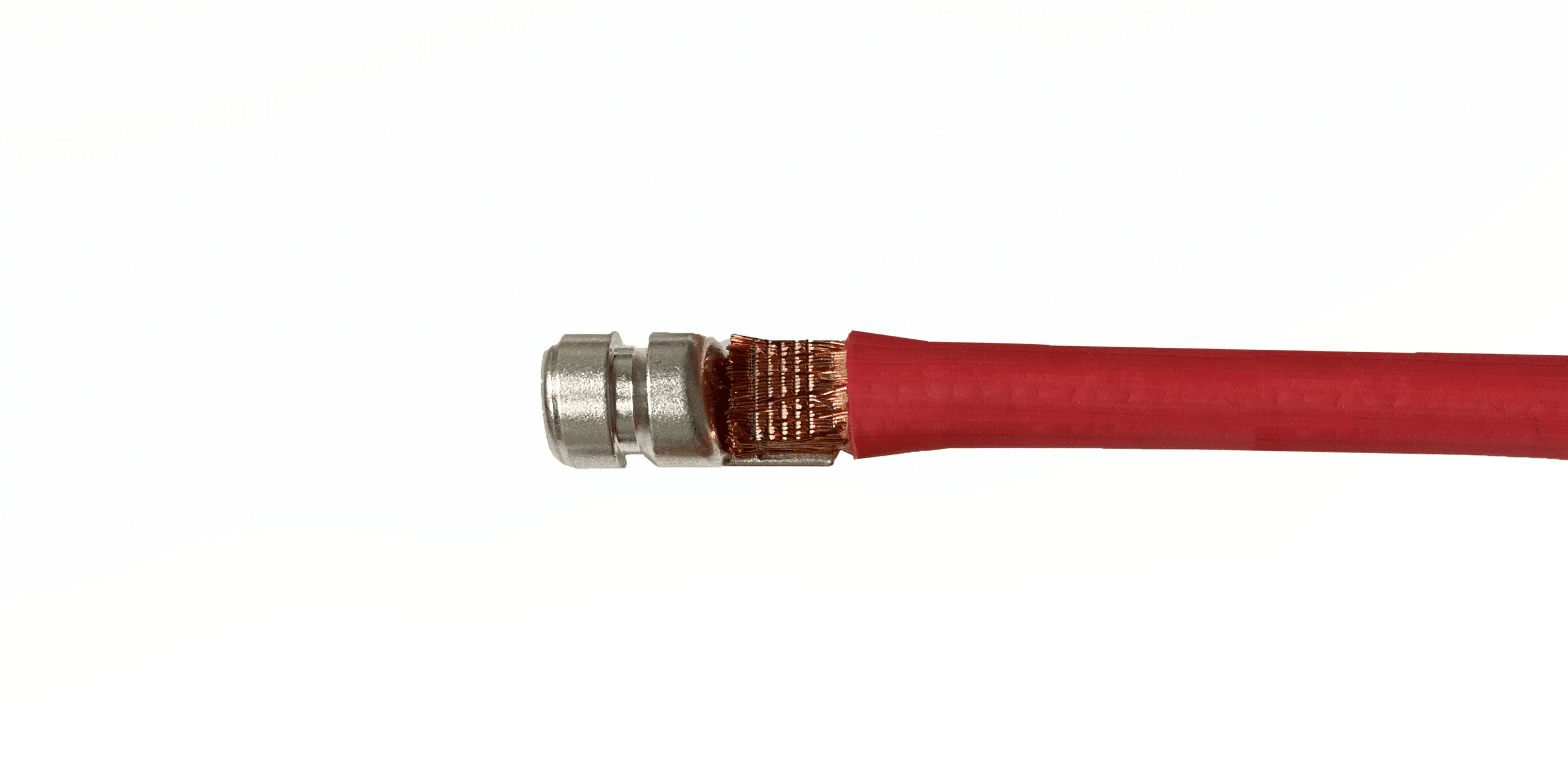

High Voltage Cable Welding Samples

Related Products

CLC Ultrasonic Wire Splicing Machine

US-3620WS2P

CLC Ultrasonic Ring Termination Welder

US-3620SRT

CLC Reel-Feed Terminator

US-3620MAK-S

CLC Large Cable Termination Welder

US-3620STH