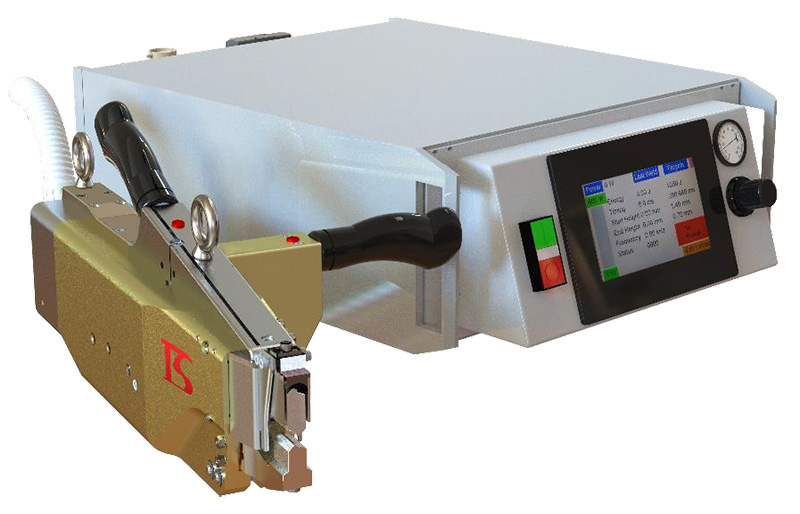

Ultrasonic Tube Sealer

TS-20TS EX

We are the Main Global Supplier of Tube Sealing System for:

TS-20TS EX

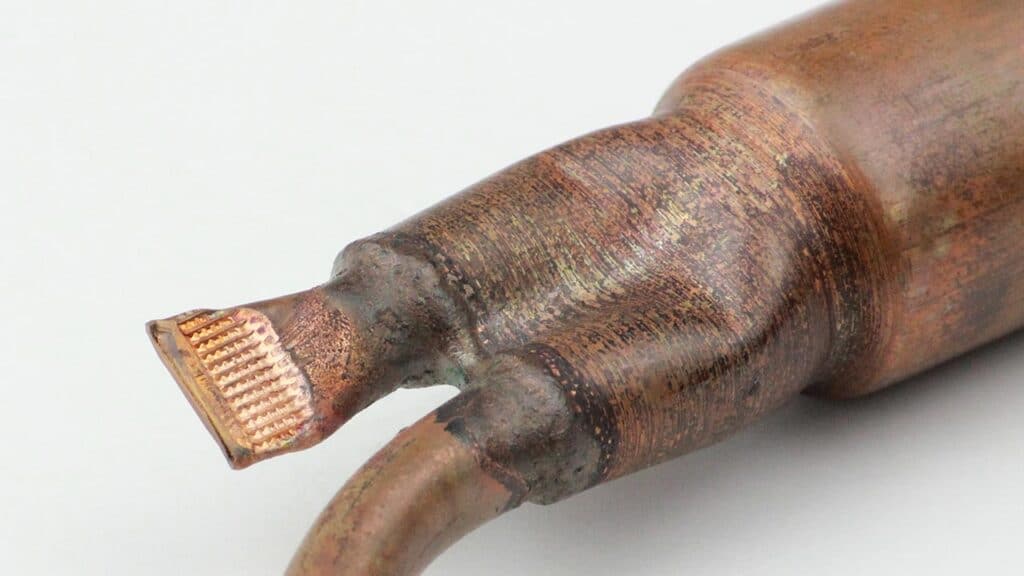

TECH-SONIC’s ultrasonic metal tube sealing machine, model TS-20TS EX “Explosion Proof” provides a spectacular solution for a large array of metal tube sealing applications. The TS-20TS EX is a one-step weld and cut process. There is no heat applied and there are no consumables needed. Ultrasonic welding creates the highest quality weld; a strong, surface molecular, solid-state bond that is clean and consistent. TECH-SONIC’s ultrasonic metal tube sealing is an easy-to-use sealing solution with low maintenance and tooling costs.

Ultrasonic Welding Advantages for Tube Sealing

Ultrasonic Welding for Tube Sealing applications is advantageous due to the following factors: it is a pure metallurgical bond for many non-ferrous materials, ability to weld dissimilar materials, fast cycle time, and consistent weld quality.

Features and Benefits of Ultrasonic Welding for Tube Sealing Applications

- Simple one-step calibration using 3mm pin gauge

- Precise measurement of pre-weld and post-weld height

- No need for outside consumables used in current crimping and soldering methods

- Tooling can last over a million cycles with small wire splices

- Operates at 20 times less energy than resistance welding