Closed-Loop Control

Cylindrical Battery Welding

TS-40 Winder Welder

Patented Technology

Cylindrical Battery Welding

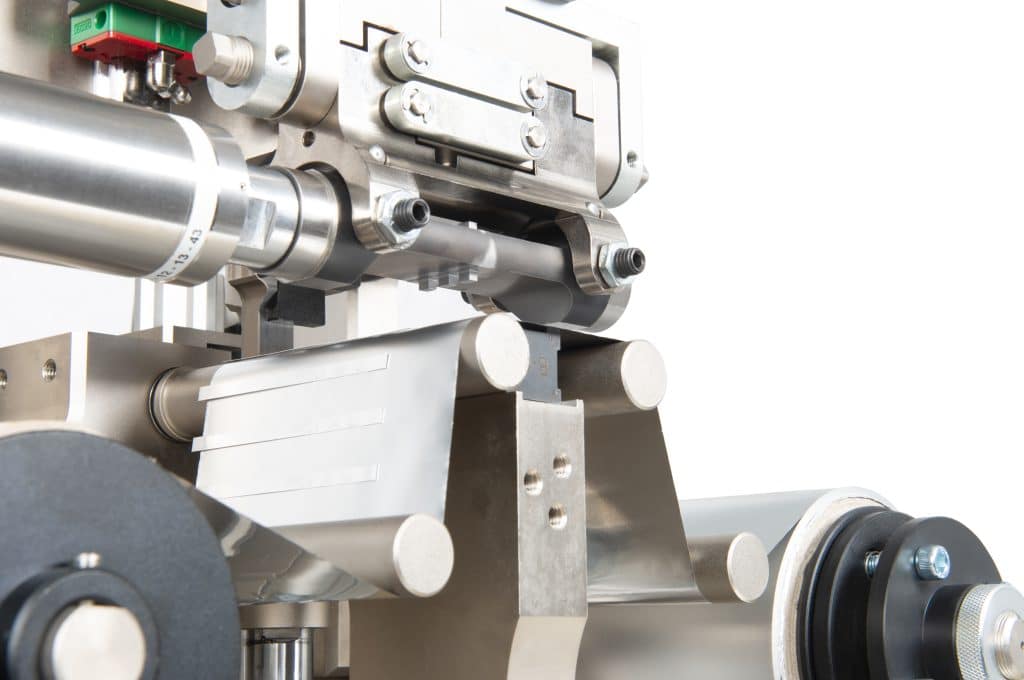

In recent years in battery production, cylindrical batteries are the most widely produced EV batteries. Cylindrical batteries are ideal due to their packaging and because they are easy to manufacture and provide good mechanical stability. Cylindrical lithium batteries have electrodes enclosed in a cylindrical cell that is tightly wound within a specifically constructed metal casing. In the early stages of creating cylindrical batteries, conductors/tabs are welded to the foils with a Winder Welder machine. However, the conventional winder welder machine has had little if not any changes or upgrades to improve the quality of the welds since the beginning of cylindrical batteries.

Since there have been little upgrades over this period of time, there have been quality issues that have arisen when welding the tabs to foils. The main quality issue is not being able to control the alignment of the horn. By not being able to control the alignment of the horn, many problems have occurred such as the cracking of the foil, uneven and misalignment that can cause a short circuit, and cannot detect missing tabs on the foil. By discovering these key issues, TECH-SONIC has come up with a technology “game changing” solution. The two most important features that TECH-SONIC has developed to “revolutionize a better winder welder machine” is the self aligning system and a generator that can measure the start height and end height in microns of each and every weld.

Advantages for TECH-SONICS TS-40 Winder Welder Machine

This new and improved Winder Welder system has a self alignment mechanism which allows for quick alignment of the horn against the anvil. This eliminates the margin of human error and saves a drastic amount of time. Secondly, the generator can measure the start height and end height of the weld which serves as a quality control window against short circuits. This critical quality control component can save a company millions of dollars and allows for welds to be scrutinized with the highest precision.

Features and Benefits of Self Alignment System in Cylindrical Battery Welder

- Horn is stable as it is fastened with set screws in the nodal point

- No loss of energy because there is no polar disc

- Consistent and precise delivery of energy

- Even distribution of amplitude in the welding area

- Quick alignment of horn against the anvil due to self alignment mechanism

- Prevent misalignment of horn that will causes pinching in the material which can cause a short circuit

- Quality control window by start height and end height of the weld